No more exploding phones: How Samsung is fixing its bad batteries problem

Following the multiple explosions and subsequent global recall of Samsung's Galaxy Note 7 smartphone in October, there was a prolonged and awkward silence from the South Korean company. On 22 January, all of that changed as Samsung finally disclosed the lengthy findings as to what caused its phones to explode.

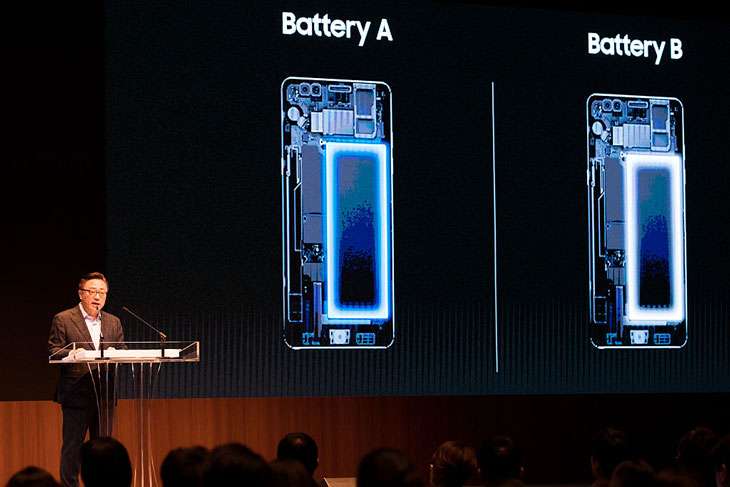

During the press conference held on Sunday, Samsung pointed to a defect in the original set of batteries and then a separate defect in the replacement set. These 'defects' caused both batches to overheat beyond repair.

The investigation was conducted with 700 dedicated staff testing 200,000 phones and 30,000 extra batteries. The company had also commissioned three outside firms (TUV Rheinland, UL and Exponent), all of whom sent back similar reports.

The root of the problem

The first set of the batteries had a design flaw. "The battery's external casing was too small for the components inside, causing it to short-circuit and ignite," according to reports.

For these batteries, sourced from Samsung SDI, there simply wasn't enough room between the outer casing of the battery and its internals. When going through the normal alternating cycles of charge and discharge, there wasn't enough room for the expansion and contraction of the battery and that caused the friction. "The positive and negative electrodes to touch, short-circuiting the battery."

The second set of batteries, from a different supplier - Amperex Technology Limited, had an entirely different issue caused by Samsung's rush to manufacture enough batteries to replace the original defective batteries.

As a result, the manufacturer introduced a 'manufacturing defect', effectively sealing the fate of the Galaxy Note 7.

Battery B had some cells missing the insulation tape. 'Manufacturing and quality' was to blame, according to the reports. The problem occurred as a result of Samsung pushing the supplier to its production limits. Some of the batteries had sharp protrusions inside the cell. This led to damage to the separate between the anode and cathode. "The batteries also had thin separators in general, which increased the risks of separator damage and short circuiting."

It is reported that Samsung wanted 10 million batteries from the supplier and Amperex just couldn't keep up.

Consumer Product Safety Commission officials were angered with the way the recall happened. They had approved the initial recall from the company and trusted their assurance that the replacement model wouldn't face the same issues.

Next step for Samsung

But how could an industry giant like Samsung have allowed this to happen? How exactly did the batteries pass the "quality and assurance process"? How was it unable to catch the problem?

"Samsung would have had to do an X-ray test on Battery A to find the problem, while Battery B would have required Samsung to disassemble it to find the error. Neither of those were steps in Samsung's normal testing process but were handled by the battery manufacturers," D.J. Koh, Samsung's mobile chief said.

After this fiasco, Samsung seems to have learned from its mistakes. The company has said that it has implemented a new eight-step process for all of its lithium ion batteries. It's also going to form a battery advisory board, comprising academics from Cambridge, Berkeley, and Stanford.

Samsung's new eight-step battery safety check includes: "durability testing, visual inspection, x-rays, charge and discharge tests, tests of total volatile organic compounds (TVOC), disassembling tests, accelerated usage tests, and open circuit voltage tests". The first three of those tests were already being conducted by Samsung. The addition of five more steps makes the process 'enhanced' and well-equipped so that another problem of this magnitude doesn't occur.

The upcoming Samsung Galaxy S8 is the first phone to have undergone these new tests.

At the end of the event, Koh signed off by saying that Samsung will be sharing all of its lessons from this with the entire industry. This is to improve the overall safety of lithium-ion battery.

First published: 23 January 2017, 8:21 IST

![BJP's Kapil Mishra recreates Shankar Mahadevan’s ‘Breathless’ song to highlight Delhi pollution [WATCH] BJP's Kapil Mishra recreates Shankar Mahadevan’s ‘Breathless’ song to highlight Delhi pollution [WATCH]](https://images.catchnews.com/upload/2022/11/03/kapil-mishra_240884_300x172.png)

![Anupam Kher shares pictures of his toned body on 67th birthday [MUST SEE] Anupam Kher shares pictures of his toned body on 67th birthday [MUST SEE]](https://images.catchnews.com/upload/2022/03/07/Anupam_kher_231145_300x172.jpg)